The difference between rubber and plastic products shred by Double shaft shredder

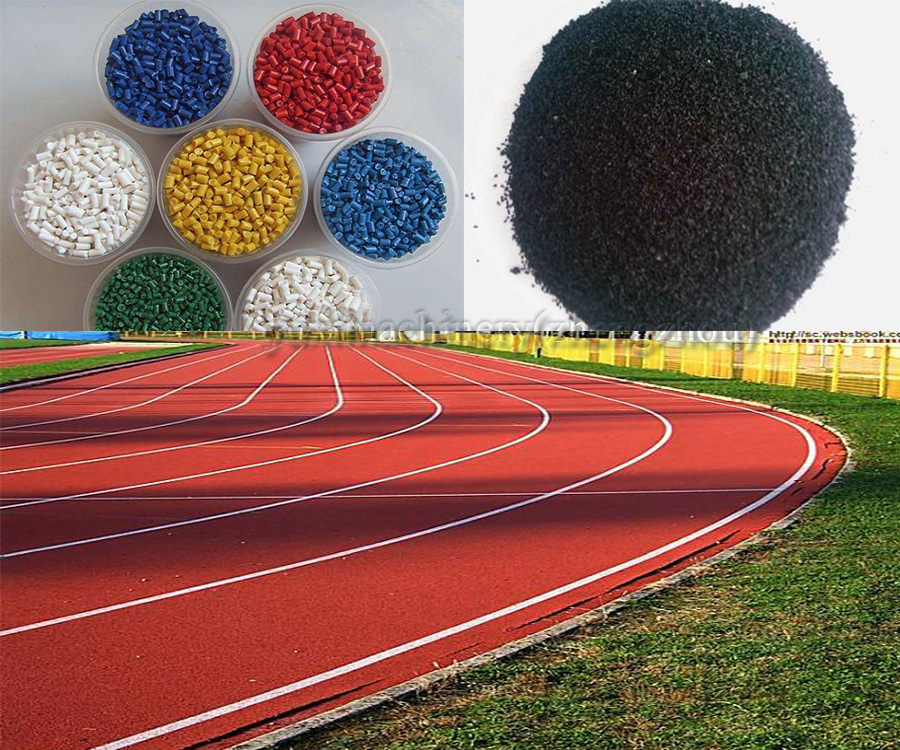

The twin-shaft tire shredder shreds plastic, rubber, metal, wood and other materials.Among them, plastics and rubbers have high recovery value and can be processed into small particles by a double shaft tire shredder to make new items. The plastic and rubber processed by the shredder can be made into a runway to achieve resource reuse. So, what is the difference between the rubber and plastic treated by the tire shredder on the production runway? Plastic runways and rubber runways differ in terms of materials and construction methods. Rubber is elastic, insulating and impervious.The rubber granules shredded by the tire shredder can be directly applied to the rubber runway, and can be made into coils in advance and directly taken to the site for convenient and fast. Plastic runways are mainly composed of plastic and other inorganic elements.The shredded plastic particles of the shredder must be melted, and then cooled to a specific shape before they can be made into a plastic runway. The engineering is complicated, but the ground flatness is not high. Whether it's a plastic runway or a rubber runway, the rubber and plastic contained in the runway can be recycled and reused by a twin-shaft shredder to create new value.

Yuxi Machinery is a supplier and manufacturer of solid waste recycling equipment.

We mainly provide production equipment, technical support, spare parts service, maintenance and so on for customers' solid waste recycling. The products involve a single machine or supporting production lines in the fields of plastics, home appliances, metals, tires, and wood.

|

Tel:0086-0371-53762053

Tel:0086-13674998188

E-mail:zhengzhouyuxi@yuximachine.com

Whatsapp:0086 13674998188

Skype:yuxi.zhengzhou

Wechat:8613674998188