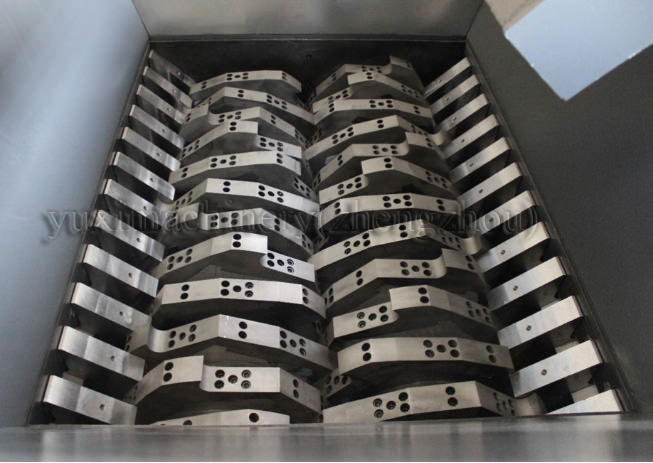

Raw material for the center blade of the shredderNowadays, the range of shredder blades is more and more widely used. The selection of tire shredder blade materials is directly related to the processing power of waste materials. Therefore, how to accurately select the raw materials of the tool is very important. Yuxi Machinery thinks that under the premise of the same processing skills, the choice of raw materials directly determines the ease of use of tire shredder blades. The tire shredder blades are divided into two categories, single-axis tools and multi-axis tools. The material selected for the single-shaft tire shredder blade is relatively simple. Most single-axis tire shredders use 9CrSi and Cr12MoV.In the subsequent production, we found that the uniaxial shredder blade made of Cr12MoV has an increasingly excellent cost performance, so nowadays high quality single-axis knives mostly use Cr12MoV raw materials. Multi-axis tyre shredder blades are commonly used in many raw materials. According to the classification, they are mainly divided into mold steel and tool steel.Due to the very good wear resistance and hardenability of the die steel raw materials, DC53, D2, SKD11, Cr12MoV and the like are commonly used.Tool steel is cheaper and has better resistance and impact resistance. It is commonly used in the shredding of plastics. The commonly used raw materials are 6CrW2Si and 9CrSi. The selection of the material of the tire shredder is like creating a foundation for a house. The foundation is solid and the house will naturally be more secure.

|

Tel:0086-0371-53762053

Tel:0086-13674998188

E-mail:zhengzhouyuxi@yuximachine.com

Whatsapp:0086 13674998188

Skype:yuxi.zhengzhou

Wechat:8613674998188